Vontoc’s injection molding service delivers high-quality custom parts fast, with end-to-end visibility and dedicated support from DFM to delivery.

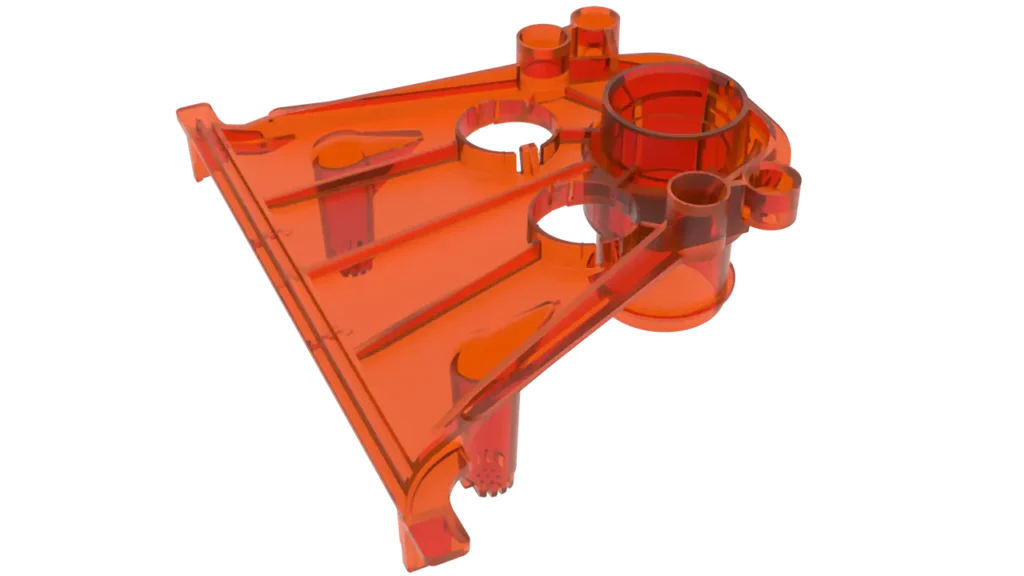

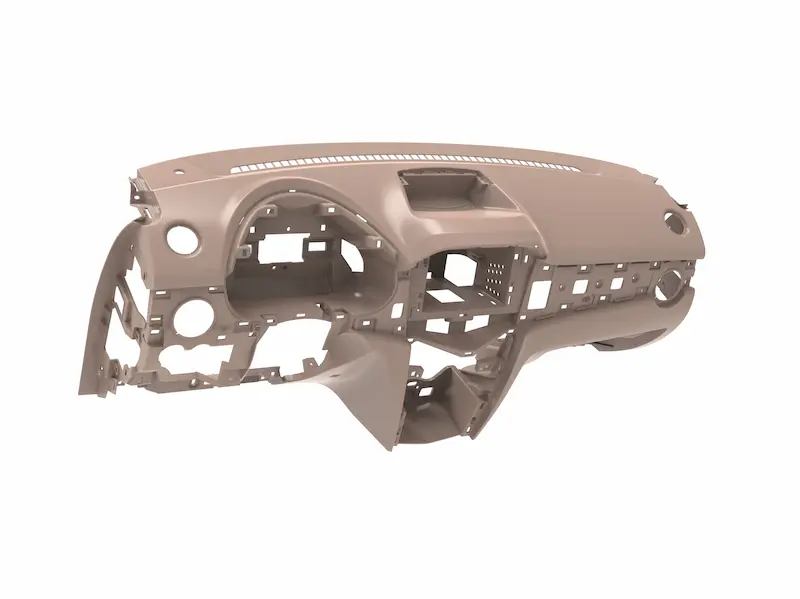

High-volume production of precision plastic parts using custom molds.

Innovative plastic molding solutions tailored to your application needs.

Efficient process from design to quality-approved production.

Selecting the ideal plastics for performance, cost, and durability.

Enhancing part geometry for manufacturability and functionality.

Precision molds for high-quality, consistent production.

Sample validation before full-scale manufacturing.

Efficient, high-volume production of molded components.

Rigorous testing to ensure defect-free parts.

| Class | Description |

|---|---|

| SPI | from mirror gloss to matte finishes |

| VDI | matte/satin finishes |

| Custom Textures | woodgrain, geometric patterns, etc. |

| Sandblasting | uniform matte surfaces |

| Method | Applications |

|---|---|

| Pad Printing | Curved surface printing |

| Screen Printing | Large-area graphics printing |

| Laser Engraving | Serial numbers, barcodes |

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.